With winter snowmaking and grooming operations fast approaching—for a select few, perhaps within a month—it’s time to consider how to make progress in the never-ending quest for better, more efficient grooming. What are the best practices to achieve that?

When trying to establish your own set of best practices, first examine current procedures and why things are done the way they currently are. Every mountain has its own unique history. There might be things you do based off past experiences that are no longer relevant on today’s modern machines. Conversely, there could be a very valid reason for what your operators are doing, but they might have not communicated that to you.

To kick-start your thinking, we asked some respected operators and suppliers for their top five tips. Here’s what they said:

Elia Hamilton, Director of Freestyle Terrain, Peak Resorts

1. Know when to quit. If you have the snow worked up into such a lather that shaping it or traction become an issue, drive away and give it some time to set up. Find another pile to ruin.

2. Work uphill. Pushing snow uphill allows for far superior snow control and placement. While it may seem less productive, one can fill holes and create dams with far less snow this way, actually saving time and material.

3. Groom from the outside in. Unless you are trying to fill a trail edge or feature corner, it is best to consolidate as you go. As an added benefit, you will not be wasting yards of material, pushing it into the woods where you will never get it back.

4. Keep a sacred zone. For jump building especially, designate a region or snowmaking whale as your takeoff snow. Treat it like a sacred burial ground until you are using it for what it was intended for. Establish an average trail depth you think you can accomplish, and then leave it alone!

5. Clean as you go. Nobody likes a messy kitchen! Don’t leave cleanup for tomorrow. Keep your push roads neat, edges tidy, and the general area organized. Be disciplined, just like a professional. That way, you won’t encounter surprises when you're backing up, distracted by the texting you are doing.

Patrick Torsell, Grooming Supervisor, Ski Cooper, Colo.

Here are five thoughts from a general grooming operations perspective.

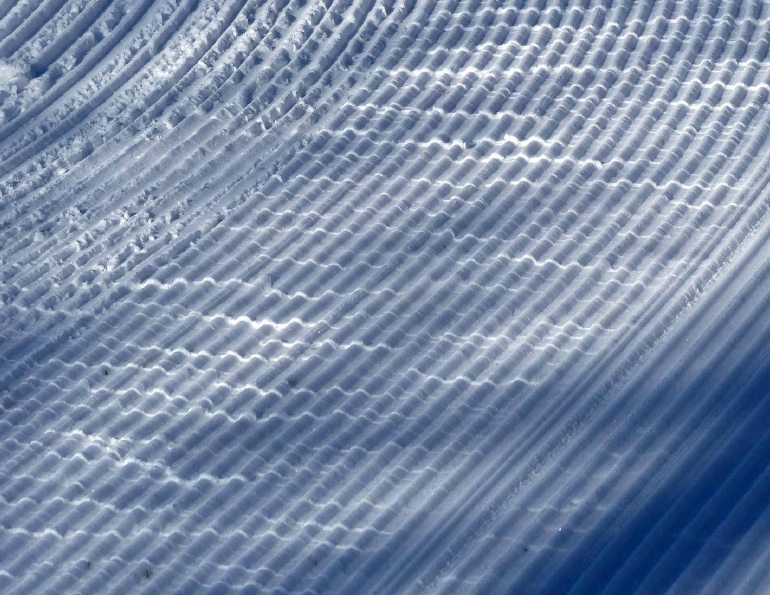

1. Be a dynamic operator. That is, don’t just “set it and forget it.” In the course of a single shift, the snow surface can vary immensely from trail to trail, from upper to lower mountain, from aspect to aspect. Cranking your tiller to 100 percent all the time may make visually pleasing corduroy, but it won’t always make a good skiing surface. Be aware of the snow surface under your machine, and adjust implement settings, speed, and blading techniques accordingly.

2. Communicate well, especially when you mess up. We all make mistakes (festering a big coffin that can’t be repaired without a day to set up, leaving an ugly ridge or windrow). The worst thing you can do is just hope nobody notices. Skiers’ safety (and your job) may be at risk. Inform your supervisor and ski patrol when something goes wrong. A supervisor would much rather hear about a mistake directly from an operator than from ski patrol or guest services.

3. Remember the goal. We groom to make a pleasing skiing surface for our guests. Everything that we do as snowcat operators should be geared toward making the best possible skiing experience. All else should be secondary (though the accounting department may occasionally disagree).

4. Take ownership of your cat and treat it well. That means keeping it clean inside and out, and being cognizant of how your operation of the machine affects its mechanical, hydraulic, and electrical systems. A clean cab will ensure a comfortable work environment for you and your fellow operators. Being aware of the snowcat’s systems, and not abusing it, will mean fewer breakdowns and less frustration for you and the vehicle maintenance team.

5. Encourage variety of terrain, especially if you are a grooming supervisor. Consider seeding moguls, and shaping some small rollers and spines—separate from your terrain park—to offer terrain variations for the guests. This also provides more options for the ski school.

Anthony Wertin, Terrain Park Grooming Svsr., Keystone, Colo.

And here are a few terrain park tips.

1. Grading. Make sure you are grading the trail flat around all the terrain park features and other obstacles that may exist on the trail. Keep the trail depth consistent.

2. Bomb holes and ruts. Properly fill in all bomb holes in the landing zones, and get rid of any ruts going into the features. This will make the tilling process look very clean and consistent.

3. Have a proper pattern so you are not leaving bumps and ridges that may affect riding into or out of terrain park features. Focus on keeping your grooming passes up and down, trying to avoid making turns so you do not make small ridges between your passes.

4. Be consistent. Keep your daily maintenance consistent by not changing the takeoffs, landings of jumps, rails, jibs and other transition features unless it is completely necessary. Consistency is the key to a great terrain park product.

5. Maintain landings for the rider. As a general rule, but not in all cases, maintain jump landings by climbing and keeping them as steep as possible. When maintaining a landing, be sure to keep the same pitch from knuckle to the toe, as this will help the landing/sweet spot feel longer and safer for the rider.

Jay Rydd, Branch Representative, Kässbohrer

1. Communication is job #1. Communication between drivers and mechanics helps the shop diagnose machine issues without wasting time looking in the wrong places. It also helps you as an operator understand what is going on with your machine. Communicate about other aspects of resort operations, too: you are out on the hill when no one else is, and you might see issues or potential hazards others need to be aware of: fallen trees, chairs iced by snowmaking, or snowmaking equipment that needs to be moved or adjusted during your shift.

2. Always have a plan, but adjust it as your shift (or week) progresses. Years of experience give you the ability to read the conditions, and to know what your end product will be before you even start. For example, if you are fighting warm temps and the weather is due to change later in the week, it might be wise to wait until the snow can set up before you attempt a big push. A good plan always has some flexibility.

3. Take your time. Grooming is like vacuuming your carpet. If you go over it really fast, it looks cleaner than it was, but you can do a better job if you slow down a bit. Also: if you feel beat up at the end of your shift, you are likely beating up your machine even more. There is a time and place for pushing the limits, but that shouldn’t be all night, every night.

4. Be efficient with your patterns. Tweak them when you can to get more done. The more efficient your patterns are, the more predictable your night becomes—allowing you time to take on extra projects.

5. Focus on the end goal. It can be hard to stay focused on the end goal when you still have a long way to go. Don’t be afraid to stop, drive around, and look at things from a different angle. Or, come back to it with a fresh set of eyes after a short break. You may decide to change your approach. In the park, sometimes your focus can be so strong that you keep trying to build a feature in a location that may not work. (See 2, above.)

David Hunter, National sales and marketing director, Prinoth

1. Choose the right tool for the job. Evaluate the project and use the correct vehicle for the best outcome and least wear and tear on the equipment. You’ll complete the job in the quickest and most productive way possible.

2. Know how much material that you are going to need. Use a probe or, better, a snow depth sensor to determine how much material you need to push. This pinpoints where the caches of snow are located. A sensor allows you to access this information without getting out of the vehicle. Overall efficiency will increase and your snowmaking efforts can be optimized.

3. Sometimes bigger is better. There are times when a free groomer can do the job, but also times when a winch will get the job done quicker, with less impact on the vehicle and the snow.

4. Make sure your tools are in the best shape possible. Perform the maintenance your equipment needs, and resolve all known issues before you hit the slopes. You don’t want to be stuck on the hill because your vehicle wasn’t maintained properly.

5. Experiment with the newest innovations and equipment. As grooming needs expand, the technology to meet those needs expands, too. Push the use of new technology to the limits. This gives you new capabilities, and that drives suppliers to bring new innovations to the market.