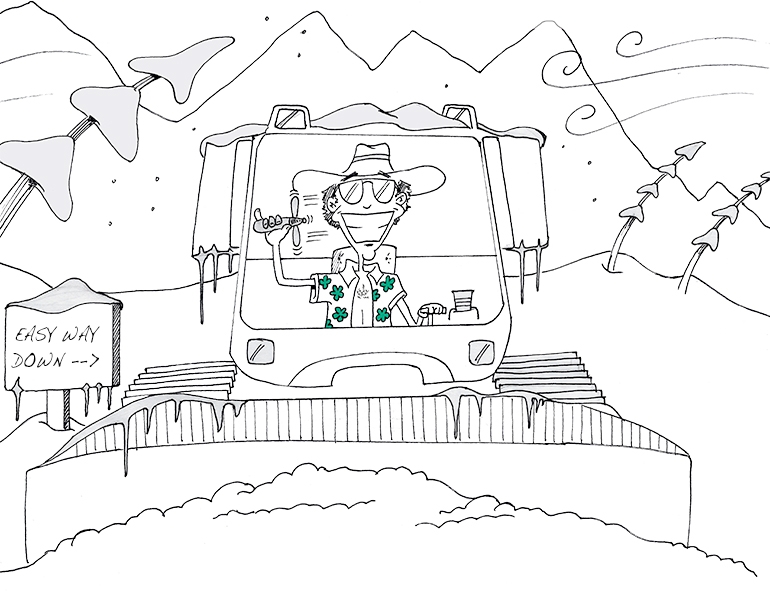

There’s a chill in the air, the leaves have fallen, and there’s even been a bit of snow. If you’re like me, you’re itching to get back in the cat. But whether you’re a rookie stoked for your first season at the sticks or a 30-year vet who can groom in your sleep, it’s always good to temper the early season excitement with some real consideration of safety—your own, of others, and the cat’s.

Your Safety

Complacency about your own safety can lead to life-changing injuries, and major loss and difficulty for you and the resort. Keeping safe out there will allow you to enjoy and excel at the greatest job on earth: operating snowcats.

1. SLIPS, TRIPS, AND FALLS. We groomers are exposed to many opportunities to slip, trip, or fall. Snow, ice, and water join with metal to conspire against us. So, as you get back into the groove this season, remember to keep multiple points of contact while you mount and dismount your machine. Resist the urge to climb without handholds, or to hop off the tracks. Any time you are walking on the machine, keep a solid handhold. Make sure you have boots with good tread for ice and snow. This is especially important if you have to walk on the trails for any reason (such as hooking up a winch cable).

2. PREPAREDNESS. In addition to wearing a good pair of boots, be prepared for anything. It’s easy to kick back in the comfort of a modern cat’s advanced climate control and comfy seat. But outside it might be a blizzard in -30º temps. Don’t leave the shop without a winter coat, heavy gloves, a hat that covers your ears, and a flashlight. It’s even a good idea to throw a pair of goggles in your pack. Assemble anything you might need for a worst-case breakdown, and take them with you every night.

3. COMMUNICATION. A lot of mistakes and incidents can be traced to poor communication. Make sure you understand what you’re supposed to be doing. If you’re unsure, ask. If you’re not sure how something works, or where you’re going, where you are, or where you should be, just ask. It’s much better to swallow your pride and admit you don’t know than to risk injury (or lose your job). If you have a concern or notice a problem, say something! If you mess up, own it. You’ll earn respect, and it will save you a lot of trouble in the long run—as long as it doesn’t become a regular occurrence.

4. SHIFT WORK. Working odd hours is a shock to the body. Make sure you’re getting enough sleep, and pack a hearty “lunch” to have mid-shift. Try to keep a consistent work-eat-sleep schedule throughout the week. Any drastic changes to this routine could harm your attention and preparedness on the job. And if you ever really do think you might fall asleep at the sticks, please stop. Find a safe place to get 15 minutes of shuteye. I don’t know a single grooming manager who wouldn’t prefer you take a 15-minute nap than run your cat off a drop or into a building. Don’t make a habit of napping, but your safety is important.

Safety for those NEARBY

When you’re operating any piece of machinery, you have to be constantly aware of your surroundings. During the night, we’re often not expecting to see anyone around us. However, with the increased popularity of uphill traffic and the realities of park building and snowmaking at many of our resorts, there are sometimes skiers, skinners, hikers, and other workers on the mountain at night.

5. HIKERS, SKIERS, SKINNERS. They will be present. Familiarize yourself with your ski area’s uphill access policy, and encourage your management team to do everything it can to educate nighttime users about the policies. But regardless of what policies are in place, people will still manage to turn up near your machine.

I recall doing a cleanout project at the bottom of a lift one night around 11 p.m., back dragging snow out onto an open run. I was clearly visible, and had been making the same back and forth motions for several minutes already. I had grabbed my next blade of snow and started backward when I just barely caught sight of a headlamp in my mirror. An uphill skier decided to skin right over the tracked snow, directly behind my machine, while I was actively working. Scared the hell out of me, and it took a minute to regroup. I couldn’t fathom the stupidity or the audacity. And yet there he was. If I hadn’t been checking my mirrors, I would have run him over.

Keep your head on a swivel, check your mirrors regularly, and keep an eye uphill and toward any intersections. If it’s safe to do so, stop your machine until people are no longer nearby or approaching. If it’s not safe to stop, try to give them as wide a berth as possible, and make sure they know you’re there. Turn on your beeper, your strobe, and honk your horn, especially if they are too close for comfort. If you’re winching, always follow your company’s procedures for signage, lighting, and other practices to alert the public to the presence—and danger—of a winch cable.

6. WORKING WITH GROUND STAFF. If you are working with staff on the ground, remind them to be cautious around machines. Emphasize the importance of making eye contact, and to never approach the machine without the expressed approval of the operator. Remind them that you have blind spots. Keep in contact via radio whenever possible. Avoid sudden direction or speed changes. If a coworker does need to approach the cab, set down your blade, throttle down, and set your brake before waving them in. Again: keep your head on a swivel and be aware of your surroundings.

safety for the machine

Safety topics often center on people, but we can’t forget the safety of our $300,000+ machines, either. Snowcats are exposed to a very harsh environment every night. That’s especially true during pre- and early-season operations when there are more obstacles and less consistent operating conditions. This isn’t just for the health of the cat; a machine in disrepair can also present a hazard to your own safety.

7. PRE-OPS. Always complete a thorough pre-operations inspection. You can save yourself from getting stranded, and save your resort from unnecessary expense, by taking a good look at fluid levels, operability of all functions and lights, and visible condition of tracks, wheels, tires, hoses, frame, etc. Trust your instinct: if something doesn’t look, sound, feel, or even smell right, report it.

8. BE A SMOOTH OPERATOR. Some people make smooth movements and actions naturally, while others tend to make more sudden and drastic changes. When operating heavy equipment, the smooth operator gives his machine a better chance of a long and happy life. Smooth and deliberate turns, forward/reverse changes, blade and tiller movement, and engine speed will help avoid over-pressure and early wear.

9. TAKE IT EASY WHEN IT’S THIN. Use extra care early season (or any time you’re working in an area with protruding obstacles). Take it slow, and be aware of how obstacles may affect tracks and implements. Don’t do what I did a few years back, when I got a bit aggressive filling in a water bar and managed to lose an entire tandem from a BR275 without noticing it until the VP of mountain ops radioed to suggest I start searching for my wheels.

10. DON’T JUST “SET IT AND FORGET IT.” A good operator is always dynamic, making adjustments for the conditions. Don’t get stuck in the bad habit of cranking everything to max (RPMs, tiller speed, tiller depth, etc.) every night. Make smart adjustments every night—and even throughout the shift—to provide the best product while using the least fuel and placing the smallest amount of stress on the machine.

11. COMMUNICATE PROBLEMS. If something goes wrong or seems off during your shift, be sure to communicate it clearly to vehicle maintenance. The most common complaint I’ve heard from mechanics is that we operators either scribble unintelligibly, or report problems like “it didn’t run right.” Be concise, but be specific. Explain the symptoms, and anything that you think may have caused or led to the problem. Having done all that, be patient if they ask for clarification, since most mechanics aren’t actually operators.

safety is for everyone

These are just a few of the many things we need to consider as we enter another season. Even the most experienced operators need to think about safety, because we’re all still capable of making mistakes. I’ve seen a rookie rip a chair out of a detachable terminal, and a 40-year operator back his tiller into a tree. I recall a macho mechanic who blew a $30,000 engine because he forgot to add oil during an oil change. And I admit that, a few years ago when I was distracted, I ran my cat off a catwalk and slid into a tree. I was the slopes/trails manager at the time, and one of my operators had to pull me out—I will never live it down.

Never become complacent. If you want a fun and successful career running cats, always be cognizant of the safety of yourself, others, and your machine.