Ferraris. That’s what Peak Resorts founder Tim Boyd called our snowcats when he sat down the grooming team heading into the first season that his company owned Mount Snow, Vt. I told him I preferred Porsches, but I got his point nonetheless: These incredible machines are expensive, so take care of them like they are supercars. That supercar analogy provided us with a sense of ownership over our equipment that had previously been, well, lacking.

Since that time, I have worked with or visited dozens of resorts and have seen the full spectrum of grooming maintenance facilities—from immaculate shops where you could eat off the floor to areas that can’t even fit a machine through the door. Faded paint is the only real difference in what is possible equipment maintenance-wise at these facilities, however. And maintenance is a key investment.

A well-maintained grooming machine with good records will not only be more reliable, it will fetch a higher trade value as well. So, without getting into the technical specifics of each individual machine, here is something of a beginner’s guide to grooming equipment summer service.

Putting the Cats to Bed

Before the snow is gone, gather information from the seasonal operators. Often there are nagging minor issues that won’t down the cat, but can be a real nuisance every night. If possible, have a mechanic ride in or operate each machine on the snow, running it as though in a normal grooming routine. Turn off the Skynyrd and open the windows to help hear things like loose or broken track parts, tiller issues, gearbox issues, etc.

Once it’s ready to park for the season, here are some good habits:

• Before removing your tiller, check cutter bars for wear, and check all of the matting for tears or damage.

• Take off the blade and tiller, and store them on wood stringers off the ground.

• Ensure hoses are capped and out of the dirt.

• Before removing the tracks, inspect them for broken or damaged cleats. Do you need new belts?

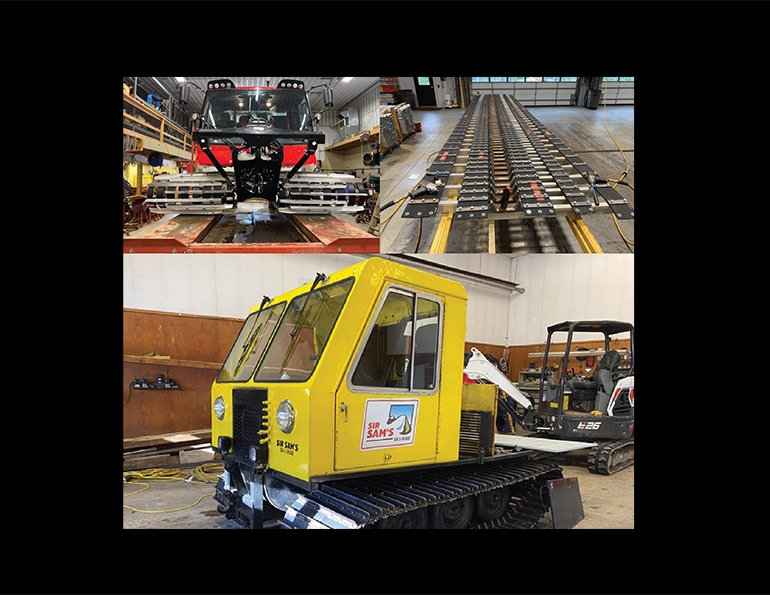

• Pull the tracks, and inventory necessary repairs before rolling them up. Look for missing bolts and damaged tire guides.

• Roll up the tracks and store them upright on pallets, either covered (wrapped in a tarp secured with bungee cords) or in the shade. Sun is rubber belting’s worst enemy.

•Perform a visual inspection of the machine, and make note of any hoses or other obvious external parts that need to be replaced.

•Store the chassis in the shade, covered, or inside if possible, to minimize paint fading. A quick wax can help with fading as well.

• Shut off your battery master switch or remove the batteries (everyone hates dead batteries!).

•Keep your windshield out of harm’s way—from either vandalism or those over-eager string trimmers that love to hurl pebbles into glass. Choose your parking spots wisely.

Checklists and Spec Sheets

When you do an inventory in spring for the parts you’ll need for summer service, it’ll save you lots of time and money—there are often pricing incentives if you order parts early.

If you haven’t already, contact your dealer to make sure you have all available summer service checklists and spec sheets. Every nut and bolt on the cat has a torque setting and Loc-Tite spec, each of which is important. The checklist will also include fluid specifications and volumes for the engine, gearboxes, and hydraulic system based on hours or calendar.

Some dealers may also have their own maintenance guides for things like track work, for example, which can be extremely useful.

Having all of this information gathered prior to bringing the machine in for service will make the actual work much more efficient. The checklist is your guide through the specifics of your machine.

Some key items to consider when it comes time to do the work:

• Do you have a good, safe way to move the machine now that it has no way to move itself? Without tracks, a free-rolling chassis can be very dangerous, and difficult to stop if it is free-rolling downhill.

• Roll the machine into the shop and get it up on jack stands or a lift.

• Pull the wheels off. Just do it.

• Basic engine work—like fluids and filters—are fairly straightforward, but if your shop is not equipped, consider having a service tech come from outside to do things like valve adjustments or to sort out fault codes.

• The interface between engine and gearbox—torque dampener or flex plate—should be inspected for wear.

• There are three gearboxes on every machine: a splitter box and two final drives. They cost big money if they fail, so be sure to service these as per the manufacturer.

• Many of the hydraulic lines can be visually inspected for cracks or damage from rubbing, but all drive hoses should be replaced per manufacturer recommended hours. Drive hose failure is messy, inconvenient, and can be catastrophic.

• Pressure test the hydraulic and hydrostatic systems. The performance and reliability of your machine depend on these systems. Hire a tech from your dealer to perform these checks if your shop is not equipped.

• Check your implement carriers and frame for even the smallest of cracks. If caught early, a little welding can prevent a much larger problem. Your manufacturer may have gusset kits available for certain areas.

• Prior to welding anything, check with your service rep to make sure you follow proper procedures so that you don’t risk damaging one of the machine’s computers.

• A coat of paint on the frame can make the thing feel brand new.

Drivetrain Work

As the final interface between the snow and power systems, the drivetrain deserves an article of its own. Between suspension, wheel bearings, sprockets, and tracks, this is an area to pay special attention. Track repair can get expensive quickly. Follow manufacturer guidelines to keep your investment rolling smoothly and reliably.

Some important steps and considerations for this stage of maintenance:

• Different suspensions require different levels of service, but they have one thing in common: bearings and bushings are cheap—whole components are expensive if the consumables are ignored.

• Apply the proper preload and grease to wheel bearings, according to the manufacturer recommendations.

• Tire pressure should be checked routinely, if applicable.

• As mentioned earlier, inspecting tracks prior to rolling them up for storage is critical so that when it comes time to work on them, you already have everything you need to get the work done.

• Building an elevated work rack for tracks can make the job more comfortable ergonomically. This may not be practical for areas with fewer machines, but is a sound investment for areas with larger fleets.

• Use wood 2x4s underneath the tracks to keep the ice picks and other jewelry off the floor. This will prevent the cleats from sitting at odd angles.

• Try to start and finish a track in one day. This will prevent “I forgot where I left off” issues, as there are a lot of bolts to remember. Have all your parts available and tools organized before bringing it in for service.

• If you are replacing belts, do one complete belt at a time, but only hand tighten the bolts until all other belts are in place. Then torque all the bolts in the manufacturer recommended pattern.

• Backing plates and the backs of cleats wear and get rough. Consider polishing them when you are replacing belting to prevent them from prematurely wearing new belting.

• Follow torque and Loc-Tite specs diligently. Don’t take any shortcuts!

Grooming equipment is a critical investment for your operation and costs as much as a supercar, so treating it like one will pay dividends. Make maintenance work easier: gather information, communicate with your dealer, and get the right parts and tools. Do the minor things, like keeping the cab clean and paint buffed, to create a sense of pride in the fleet.

Of course, things happen and machines break, but everyone will be happier if you catch as many issues as possible before those issues strand the operator on the hill. That is the definition of preventative maintenance.