Lutsen Mountains, MN

A fast-moving fire claimed one of Lutsen’s base village buildings on June 24, 2023. There were no injuries in the early morning blaze, and it spared a nearby gondola. The building, known as Papa Charlie’s, housed a popular bar, restaurant, and music venue. Its loss was widely mourned. Lutsen owner Midwest Family Ski Resorts (MFSR) immediately began working with its insurer and designers on a plan for replacement that honored the past while also improving utility for today’s guests.

Designed by LHB of Duluth, the new 7,200-square-foot structure utilizes timber frame construction and laminated wood beams. It houses an upscale bar and restaurant, along with eight lodging units, half of which are fully ADA accessible. The restaurant encompasses 3,600 square feet on the first floor, and there are four king rooms and four double queen rooms on the second floor. Some functions, like live music, have moved permanently to other spaces.

General contractor Kraus Anderson broke ground in the fall of 2024. A thousand yards of fill had to be brought in to raise the grade 5 feet (construction of a nearby road had left Papa Charlie’s in a hole that collected water at the time of the fire). Building through winter in northern Minnesota proved a challenge, particularly when it came to material laydown in a busy base village. Limited space to store materials required a lot of just-in-time deliveries, “making scheduling very important and delays particularly impactful to the overall project schedule,” said MFSR chief of mountain operations and development Benjamin Bartz.

Construction wrapped up in June following nine months of work. The hotel portion of the facility, dubbed Sunset Studios, launched at the end of that month. Charlie’s Alpine Bistro, a nod to the prior bar, debuted mid-summer, serving breakfast and dinner. The completed building includes several environmentally friendly features like water vapor fireplaces to reduce natural gas consumption and keycard occupancy-controlled HVAC in each guest room.

Big Sky Resort, MT

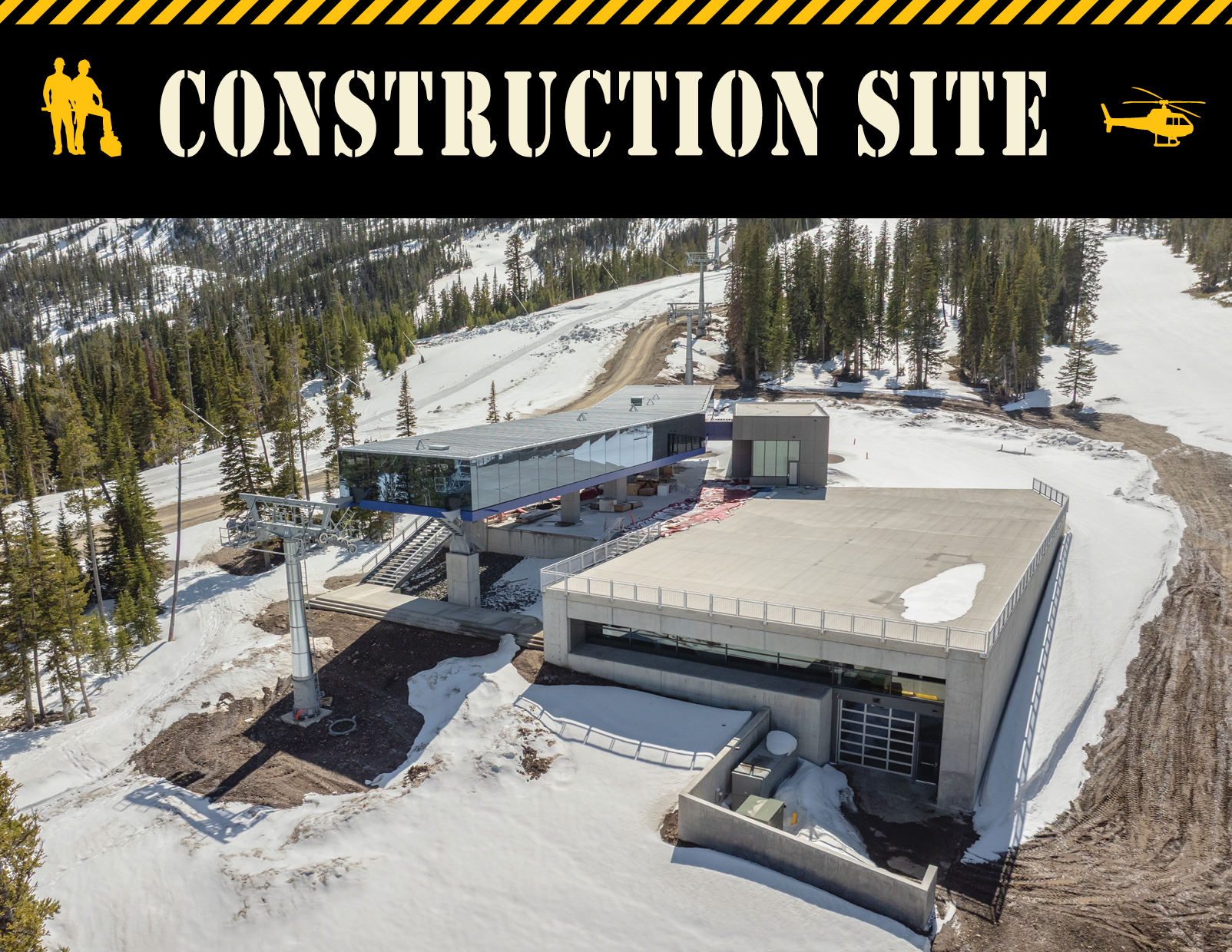

Big Sky is nearing the end of a multi-year effort to build a new out-of-base gondola. The two-stage Explorer Gondola replaces a Heron-Poma double, the last remaining chair from Big Sky’s founding in 1973. The new Doppelmayr D-Line with Omega V 10-place cabins features a mid-station near the top of the old chair then continues up to the base of Big Sky’s two-year-old Lone Peak Tram. Uniquely, a single 1,200 hp direct drive will power both sections from the middle station, with tensioning at each end terminal. The 83-cabin system will span 8,237 linear feet and ascend 1,499 vertical feet at a speedy 7 meters per second (roughly 1,378 fpm) and more than double the uphill capacity to 2,850 pph.

Big Sky commenced work on the middle station’s foundation and below-grade cabin parking facility in 2023. The upper terminal foundation followed in 2024, requiring challenging excavation, blasting, and micro piles. Local builder Jackson Contractor Group spearheaded foundation work and began installing line tower footings in spring 2024. Work on the lift’s buried communication lines commenced that summer, too. Doppelmayr mobilized in fall 2024 to install mid-station steel for the first D-Line R2 “glass box” station in the United States.

The Explorer double carried its last riders on March 30, four weeks before the rest of the mountain closed, allowing the construction team to get a jump on the bottom terminal—but a deep snowpack required the resort to remove lots of snow for construction to proceed. The two-story bottom station will have restrooms and ticketing housed beneath the lift loading platform. Normally, a building of this size would take at least a year to build. To shave three months off the timeline, designers opted for pre-cast concrete walls, fabricated off site. Each piece was brought in by truck and tilted up on poured foundations.

Doppelmayr flew 16 of the lift’s 18 towers in May, utilizing a Chinook helicopter flown by PJ Helicopters. Flying towers in early spring at 9,000 feet meant working through snow and mud to set towers weighing up to 14,000 pounds.

Some spring challenges were unrelated to weather. Doppelmayr manufactures many components for D-Lines in Austria and Switzerland, so rapidly changing tariffs on E.U. imports caused supply chain challenges. Despite the trade war, construction remained on schedule as of late July, with a load test scheduled for early December.

Park City Mountain, UT

A new signature lift will debut on Park City Mountain this winter for the first time in 10 years. The Leitner-Poma-built Sunrise Gondola replaces a short double chair of the same name but continues higher up the mountain, terminating at Red Pine Lodge. This provides a third people mover between Canyons Village and mid-mountain.

The two other lifts providing egress from Canyons Village—the eight-place Red Pine Gondola and a four-place bubble chair—run on ridgetops and regularly close in high winds. This prevents uploading but also much-needed downloading (a large canyon separates Red Pine Lodge from the village). Park City and Leitner-Poma designed the 10-passenger Sunrise to be sheltered from the north, with shorter towers and heavier cabins than the Red Pine Gondola. Once complete, the machine will span 6,500 feet with 1,091 feet of vertical.

Park City worked with the Canyons Village Management Association for partial funding and settled on a two-year build schedule to ensure timely completion. In summer 2024, crews completed initial excavation and utility relocation around the bottom terminal, all while keeping the prior double chair intact. An excavator with masticator attachment cleared vegetation from the lift line and a spider excavator followed, digging line tower foundations.

Leitner-Poma completed many of the tower foundations nearly a year prior to vertical construction.

Work paused over the winter, and the old Sunrise lift closed in late March for construction to begin anew. Laborers removed the old lift by crane, and Park City auctioned its chairs to benefit local nonprofits. A contractor brought the grade of the bottom terminal site down about 20 feet, matching the level of several new hotels. At the top terminal site, Park City staff moved a beginner conveyor to make room for the drive terminal, which houses Park City Mountain’s first-ever direct drive motor. The 38,000-pound motor assembly was transported to Red Pine Lodge using both a dozer and military-style truck.

Most of the new gondola’s 24 towers were flown by helicopter in June and July. Cabins arrived in containers from France and were staged near the bottom terminal.

As of late July, only one tower still needed to be set along with the return terminal. The haul rope was already on site, ready to be pulled much earlier in the fall than with a typical one-year lift build.

Ski Butternut, MA

Last spring, family-owned Ski Butternut retired its oldest lift, the 50-year-old Thiokol triple Overbrook. In its place, a Skytrac quad with a new-and-improved alignment is being installed. The new lift will be named Jane’s in honor of Jane Murdock, the co-founder of the ski area who died last winter. Even though the lift will go from a triple to a quad, design capacity remains the same at 1,800 pph. The design includes a 300 hp drive motor at the bottom station and bottom tensioning.

The old 1975 Thiokol posed several challenges. True to its name, Overbrook ran over a creek in a ravine. “Although scenic, it was not an ideal location for new construction or ongoing maintenance,” said marketing director Dillon Mahon.

Operations staff selected the new alignment in consultation with the Massachusetts Department of Conservation & Recreation (Butternut’s landlord) to avoid the ravine and end higher up the mountain. The new top station will eliminate an uphill trek to get to the Uptown trail, which Mahon joked could now be renamed “Downtown.”

Butternut was able to finish most of the site prep in fall 2024. A local contractor cleared a 50-foot-wide corridor, and Butternut staff graded with backhoes, excavators, and bulldozers. Skiers enjoyed a preview of the new 757-vertical-foot lift line during the 2024-25 season, and work resumed in May.

An extremely wet spring in the Northeast proved challenging, but crews worked around the weather. Butternut removed the old lift and Skytrac mobilized to install the new 3,693-foot-long quad. Fifteen tower foundations were excavated by mid-summer. No blasting was needed, and no helicopter was needed to pour concrete. Towers will be flown in by helicopter in late summer.

Butternut’s in-house team reconfigured snowmaking infrastructure around each terminal location, requiring approximately 2,000 feet of new pipe and several new snow guns. As of late July, both terminal foundations were complete, with Jane’s 124 chairs expected to be spinning by early December.

Wisp Resort, MD

Maryland’s only ski area worked all summer to improve its snowmaking system, with a focus on automation and fixed-position gun technology for better coverage. The plan was three-fold.

First, a conveyor-served beginner slope called Sunset Boulevard would receive two new guns, replacing old guns. Then, the bulk of the work would focus on Possum, a much longer beginner trail requiring 16 new guns, new lateral piping, and new electrical and communications lines. The final piece would be the installation of all new pipe, wiring, fiber lines and 10 guns on intermediate trail Grouse Way.

In the 70-year history of the resort, neither Possum nor Grouse Way previously had fixed-position guns.

Wisp’s in-house snowmaking team ordered the equipment in March. Each of the 28 new TechnoAlpin guns is fully automated. Wisp purchased a mix of 10-foot and 20-foot TL8 sticks, deployed depending on trail width. Each gun is mounted on new TechnoAlpin steel pits.

Despite adding snow guns to its fleet, Wisp didn’t need to add any additional water storage or pumping capacity; the mountain sits near Deep Creek Lake and an existing primary pumphouse can move up to a staggering 15,450 gallons per minute.

Wisp’s team broke ground on Sunset Boulevard in April. By May, they were working on all three trails to install 1,300 feet of eight-inch main pipe and 1,200 feet of two-inch lateral pipe. Several rocky areas proved challenging, requiring the use of a large excavator and bulldozer to move rock. Despite wet conditions on the mountain all spring, the project remained on track as of late July.