A hundred years ago, oil was just oil—the science of how lubricants work was in its infancy. But today, the science is refined, and modern lubricating oils often have very specific properties and uses. The educated use of lubricants is a key to both reliable and efficient mechanical operation.

Lubricants are primarily used to prevent wear, but have other uses, too. In some machinery, lubricants act to transfer heat and prevent corrosion. In applications such as hydraulics, they transfer power.

There is a specific type of lubricant made for every use. Lubricating oils consist of varied combinations of base oils and additives. The additives depend on the application, and might be as low as 0.5 percent of the volume to more than 16 percent. Some additives improve the life of the base oil, while others improve the performance of the oil. Still others, such as anti-corrosion additives, protect the materials the oil comes in contact with.

Today, most lubricants start out with a refined paraffinic—a term that refers to the molecular structure of the base oil—mineral oil. But there are a variety of other base oils that can be used in a finished lubricant, including hydrocracked mineral oils, super hydrocracked mineral oils, naphthenic oils, and a variety of synthetics such as polyalphaolefins (PAO) and polyalkalene glycols (PAG).

Viscosity is a measure of a fluid’s resistance to flow. Some liquids, such as water, have a very low viscosity, while others, such as honey, have a high viscosity. The key is that a lubricant must have the right viscosity and the right additives to do the job at the temperature(s) under which it is utilized.

Basic Applications

Before we look at those requirements, though, let’s look briefly at the basic lubricant applications:

Ball and roller bearings. At very low speeds, these act like sliding bearings. But at typical operating speeds of more than 100 rpm, ball and roller bearings trap the oil at the contact point between the rolling element and the ring. At that point the oil instantly becomes about a million times more viscous—stiff enough to actually deform the steel. This semi-solid film is extremely thin, about 1/100 the thickness of the paper SAM is printed on, and both the film and the mating parts are easily damaged by dirt particles too small to see, or by minute quantities of water.

Plain bearings. Examples of these include the main and rod bearings in your car engine and some large motor bearings. With plain bearings, if more oil is supplied to them than can leak out the sides, they will develop enough of a film to separate the parts. Usually the film is between 20 to 50 percent of the thickness of SAM’s paper, and is much less sensitive to both water and dirt. One important point is that, with plain bearings, the heavier the load, the hotter and less viscous the lubricant. So, when an operator “lugs an engine”, i.e., runs it at heavy loads at low rpm, the bearing clearances drop rapidly because the increased pressure heats the oil, reducing the viscosity, and allowing it to leak out more rapidly.

Sliding bearings. These can cover a wide range, from the individual wires in a rope as the rope goes around the bullwheel to the piston rings in an engine, and to the rod in a hydraulic cylinder or to the vanes and pistons in hydraulic pumps. With these applications, there is essentially no clearance, and water and dirt can be huge problems.

Base Oil Viscosity

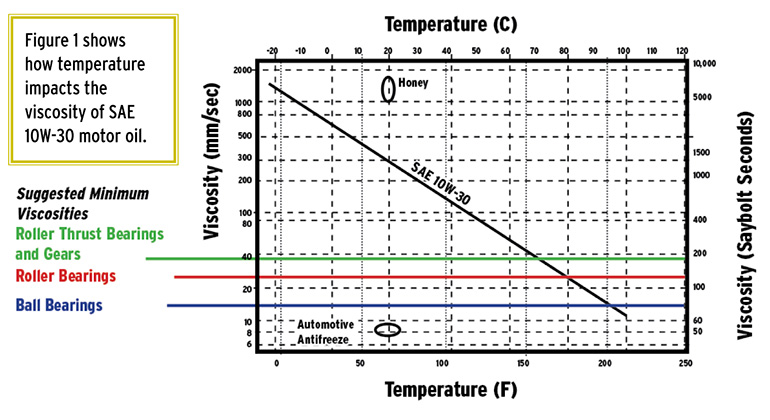

Oil viscosity changes with temperature, so the operating temperature is important. The chart in Figure 1, below, shows how an SAE 10W-30 motor oil can be as thick as honey at low temperatures, but close to water in a modern, hot engine crankcase.

If the oil viscosity is too low, damage results. But if the viscosity is too high, it reduces efficiency. That’s why modern engines specify lower viscosity oils, such as 0W-20.

In Figure 1, the older Saybolt Seconds viscosity scale, which was the traditional North American method of measuring viscosity, is on the right, and the now more common metric mm/second scale is on the left. In addition, there are three horizontal lines showing the generally accepted minimum viscosities for ball bearings, roller bearings, and roller thrust bearings and gears. Note: Be careful, because these minimums don’t apply at low speeds.

Automotive engine oils, such as the 10W-30 shown on the chart, usually have their viscosities specified at both low and high temperatures—32°F and 212°F (0°C and 100°C, respectively)—while industrial oils have their viscosities specified at 40°C (104°F) with a given viscosity index.

Viscosity Index

The viscosity index was born about 100 years ago. In the 1920s, manufacturers in different states produced different base oils made from the crude oil found in their state. Industry soon realized that Pennsylvania’s base oils did a better job compared to, say, Texas or California oils. This was because, unlike the other states, Pennsylvania’s crude oils had a paraffinic structure that didn’t thin out so readily at higher operating temperatures.

In order to recognize this difference, researchers coined the term viscosity index (VI) as a measure of how fast an oil changed viscosity. They also proposed that the Pennsylvania oils should have a viscosity index of 100. At that time, the Texas oils typically had a VI of around 50, while the California oils had a VI of less than half that.

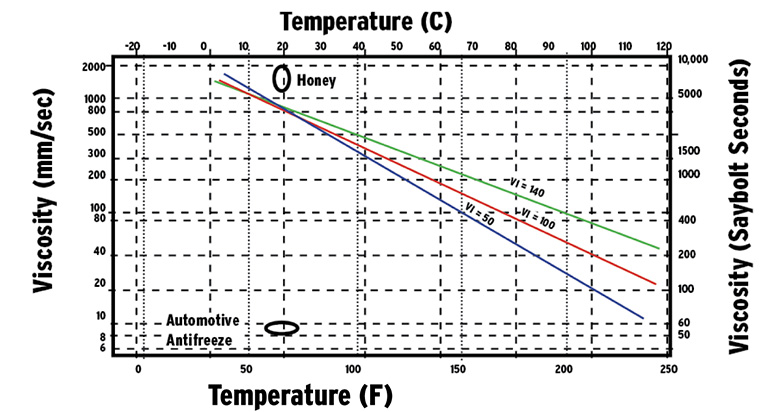

VI is a relative term, and Figure 2 gives an idea of the differences. Here we’ve used that same viscosity graph shown in Figure 1, but have added examples of three oils. These oils have the same viscosity at room temperature, but different VI.

Figure 2 shows the same viscosity graph as Figure 1 with three different oils, with different VIs.

Figure 2 shows the same viscosity graph as Figure 1 with three different oils, with different VIs.

Additives can be used to improve the VI of a base oil, but the biggest change in the last 50 years has been the result of improved refining of mineral oils and the introduction of synthetics such as the PAOs. While many common industrial oils have a VI of about 100, there are gear and automotive engine oils with VIs of 170 or more, and some specialty hydraulic oils have VIs of more than 400.

If you have a machine that never gets very cold and operates at a relatively constant temperature, such as a pump in a heated pumphouse, the oil can be specified for the viscosity at the normal operating temperature and the VI isn’t very critical. But a machine such as a groomer, which can be started at negative temperatures and then have to work hard, substantially heating both the hydraulic and crankcase oils, then the VI can become very important.

In part 2, in our next issue, we’ll look at the various additives used in oils and greases, and at some of the common problem areas.