For anyone in the market for new grooming equipment, the checklist of requirements is long. Needs to be powerful. Needs to be efficient. Needs to be versatile. Needs to be easy to operate, and easy to learn to operate. And so on.

With advances in technology, the list grows longer. As John Glockhamer of PistenBully notes, PB is focused on “two central themes: sustainability [vehicle electrification] and digitization.”

Sustainability has been a focus for years, with grooming machinery made by PistenBully and PRINOTH complying with North America’s Tier 4 emission standard and Europe’s more stringent Stage 5 standard, which was adopted in 2019. PistenBully has taken sustainability a step further with the 600 E+, its diesel-electric snow groomer. Long-term, both companies are pursuing zero-emissions solutions, with all-electric concept models currently in testing.

As for digital technology, improvements, some dramatic, have accordingly improved operational efficiencies and ease in both grooming and snowmaking.

Here’s an overview of the grooming landscape:

THE MACHINERY

While neither PistenBully nor PRINOTH has introduced a brand-new model to its 2021 groomer lineup, significant enhancements have been made. Each has a fleet of models to cover a wide range of grooming needs: big behemoths to push, till, and groom lots of snow in wide-open spaces; mid-sized machines to take care of narrower trails and more complex terrain; groomers with implements specifically designed to build terrain parks; smaller groomers that can jitterbug in tight spaces.

Top left: The PRINOTH Bison family has been the most popular of the company’s machines in the U.S. Shown here: Bison X, which offers several park-specific features. Top right: The PistenBully 600 E+ has an electronic transmission that is quieter, more efficient, and has greater torque than a hydrostatic transmission. Above left: Hands-on learning is part of PRINOTH Academy. Above right: The PistenBully 600 remains the company’s diesel-powered workhorse.

Top left: The PRINOTH Bison family has been the most popular of the company’s machines in the U.S. Shown here: Bison X, which offers several park-specific features. Top right: The PistenBully 600 E+ has an electronic transmission that is quieter, more efficient, and has greater torque than a hydrostatic transmission. Above left: Hands-on learning is part of PRINOTH Academy. Above right: The PistenBully 600 remains the company’s diesel-powered workhorse.

PRINOTH

At the top of PRINOTH’s groomer chart is the burly Leitwolf, with a six-cylinder diesel engine that can crank out more than 520 hp. With a blade that can push a wall of snow almost 20 feet wide when the side wings are open, and with a total track width of nearly 15 feet, the Leitwolf has the power, size, and traction needed to move a lot of snow over long distances.

The Leitwolf can also be used in winching applications on steep slopes. According to Andreas Muigg, PRINOTH’s head of product portfolio management, the Leitwolf is especially popular at alpine areas in Europe, where wide-open spaces predominate, and is “proven technology,” having been on the market for 10 years, with small modifications.

In North America, however, Muigg says that the most popular PRINOTH model is the Bison—a bit smaller than the Leitwolf. The Bison has been on the market for more than six years, a testament to its versatility and the viability of its design, says Muigg. Its engine can pump out more than 400 hp, so the Bison can move a heavy helping of snow. And, with a tiller that can spread to more than 20 feet when optional hydraulic side-wings are included, it can cover a wide swath in each pass.

The Bison comes in an X version to allow for park construction and maintenance as well as normal grooming. The X version includes such park-specific features as a special park blade with side cutters, extra range of motion for the blade, an additional cutting knife for sharp edges and features, and an inclinometer.

For smaller, tighter grooming applications, the Husky (like the Bison, also available in a park version as the Husky X) is capable of producing 231 hp and has a blade that, when fully extended, can work a swath of nearly 13 feet. Muigg describes it as “an interesting little machine that can do anything on the ski hill.” The Husky can also be equipped with an optional passenger-transport cabin.

PISTENBULLY

PistenBully’s 600 series of groomers comprises its biggest machines. Most notable is the 600 E+, a hybrid diesel-electric model in which the diesel engine works with two electric generators to produce as much as 512 hp. The original 600 E+ was introduced in 2012. At the end of 2020, it underwent a significant redesign.

The new second-generation 600 E+ produces 20 percent less noise and carbon emissions, consumes 20 percent less fuel, and has 16 percent more pushing power than diesel-powered PB 600 models. It sports the latest emission control systems and PB Integrated Operating controls. The latter is uniform across the PB line.

High power with low fuel consumption is made possible, in part, by the electric transmission. Glockhamer says it’s much more efficient, quieter, and has more torque than a standard hydrostatic transmission. The operator inputs to the electric transmission, and “the intelligent control system of the 600 E+ calculates the best possible operating point for the diesel engine,” he says, enabling the engine to run at a steady state and low RPM. Electrical energy is recuperated during downhill operation and fed back from the electric drive motors to the generators, further reducing fuel consumption.

The diesel-powered 600 models are still PistenBully’s “bread and butter,” says Glockhamer. The available six-cylinder engines can produce up to 512 hp. The fully-open blade is more than 18 feet wide, and the tiller can reach more than 20 feet wide with foldable side finishers extended. The Kombiplus track, with aluminum cleats and steel wear bars, now comes with seven belts for increased performance and climbability.

For applications where maneuverability might be more important than sheer size and power, PistenBully offers the 400 4F, delivering what the company calls an “ideal mix” of power, weight, and size. The Cummins diesel engine can produce 400 hp, and the blade, when fully open, spans more than 17 feet.

The 400 4F also comes in a Park Pro version, with such tools as the Switchblade, designed to do some of the detail work that might otherwise be done by hand. Also available on the Park Pro is a joystick that PistenBully calls “intuitive,” meaning that in addition to making for easier operation and operator training, puts all the controls in one hand to maintain the precision required in park building.

PistenBully lists the PB 100 groomer as a Nordic product, but Glockhamer says alpine resorts might also find it useful in tight quarters such as lift-loading areas. It can pump out more than 250 hp, and its blade opens to 12.4 feet wide.

To help operators get the most from their machines, PistenBully incorporates what Glockhamer calls “assist systems” for groomers. These include such features as Autotracer, which provides steering assistance; Slopetracer, which improves tiller precision and control; and an in-cab computer terminal to provide the groomer with guidance and operational feedback.

DIGITAL PLATFORMS

For the past several years, the major suppliers have aggressively promoted software programs designed to improve performance and management. Some of these are aimed at overall snow depth monitoring, with its implications for snowmaking as well as grooming.

The software packages from both PRINOTH/Leica and PistenBully require creation of a terrain model, using a GPS survey, for snow-depth management. That adds to the overall cost. Some grooming managers, while enthusiastic about the utility of snow-depth management software, have expressed to SAM that the capital cost has dissuaded them from making the initial installation.

Muigg and Glockhamer insist that the initial investment is typically recouped within two years, based on efficiencies achieved in both grooming and snowmaking. Muigg also notes that snow-depth management can be valuable in extending a resort’s season, both at the start and at the end. In addition, both software packages can be transferred to other machinery for summer applications.

Top left: The Leica/PRINOTH Snow How snow management system offers snow depth information at the operator’s fingertips. Top right: The PRINOTH Academy, launched last summer, brings groomer education to any resort, at any time. Below left: Snow How screen gives grooming managers the big picture. Below right: the PRINOTH Husky eMotion is the company’s fully- electric concept cat; PRINOTH says commercial introduction of an all-electric groomer is one or two years away.

Top left: The Leica/PRINOTH Snow How snow management system offers snow depth information at the operator’s fingertips. Top right: The PRINOTH Academy, launched last summer, brings groomer education to any resort, at any time. Below left: Snow How screen gives grooming managers the big picture. Below right: the PRINOTH Husky eMotion is the company’s fully- electric concept cat; PRINOTH says commercial introduction of an all-electric groomer is one or two years away.

PRINOTH

PRINOTH markets a package of software tools under the brand Snow How, which includes Leica Geosystems’ iCON Alpine snow depth measurement solution and PRINOTH’s own Fleet Management system. For resorts with mixed fleets, the hardware and software can be used with any brand of snow groomer.

“The technology makes a good operator better, and also allows a new operator to repeat, night after night, what he or she needs to do,” says Leica alpine account manager Kelly Steeves. “It works for operators on both ends of the spectrum of technological familiarity because it’s intuitive and simple. The colors, for example, are more recognizable on the panel—green represents on grade, red represents below grade, blue is above grade.”

Leica has taken technology already in wide use in construction and agriculture and applied it to the ski industry. Armed with reams of data churned out by the software, groomers can become more informed and thus operate far more efficiently. Similarly, Snow How Fleet Management provides real-time position and vehicle data, as well as reporting and other functions, for all resort vehicles to help improve overall efficiency.

PISTENBULLY

SNOWsat is PistenBully’s package of software programs that aim to make the grooming process “as operator-friendly as possible,” says Glockhamer. In addition to the snow-depth measurement and fleet management solutions, the SNOWsat suite offers digital solutions for several other aspects of operations. “The goal is to provide the ski area with increased efficiency and accuracy by streamlining operations through digitalization,” he says.

SNOWsat ToDo enables managers to assign tasks to specific individuals or vehicles, and keep track of it all. The tasks and any accompanying notes appear on the operators’ in-cab screen. SNOWsat Maintain is a cloud-based digital program for the vehicle maintenance shop. It can track costs, repairs, and downtime for all resort vehicles, and also store service records, manage parts inventory, and generate maintenance checklists, among other functions. SNOWsat Reporting provides customizable reports of slope data for evaluation and planning.

There is also SNOWsat for Building Parks, GIS Management, Snow Management, Analytics, and more.

TRAINING

Philippe Gosselin, PRINOTH North American marketing manager, points to two primary issues facing many mountain managers—“staff turnover and a lack of experience in mountain ops right now.” Glockhamer agrees, saying that “finding and keeping good operators is a central challenge” for the ski industry. Both PistenBully and PRINOTH recognize, given the shortage of experience among groomers, the need to be able to bring groomers (and maintenance technicians) up to speed quickly through training support.

Last summer, says Muigg, PRINOTH introduced its PRINOTH Academy, combining e-learning with on-site training. For e-learning, operators and technicians can choose Basic, Advanced, or Expert levels, depending on one’s existing knowledge. Operators learn the various on-board systems (controls, vehicle status display, etc.), as well as operational best practices, such as pre-start inspection, safety protocols, winch operation, etc. Technicians learn the ins and outs of the vehicle, including electrical/electronic systems, powerplant, maintenance, and more. Software enables managers to track and test their staff’s performance.

PistenBully introduced its Pro Academy four years ago, similarly integrating online learning with hands-on training for groomers and technicians. PistenBully tailors any training curriculum to match the specific grooming fleet and snowmaking set-up of any particular resort; no need to complicate the learning process with instructions for equipment not directly applicable to a mountain’s operations. When training is successfully completed, “graduates” are acknowledged with a certificate to affirm their qualifications.

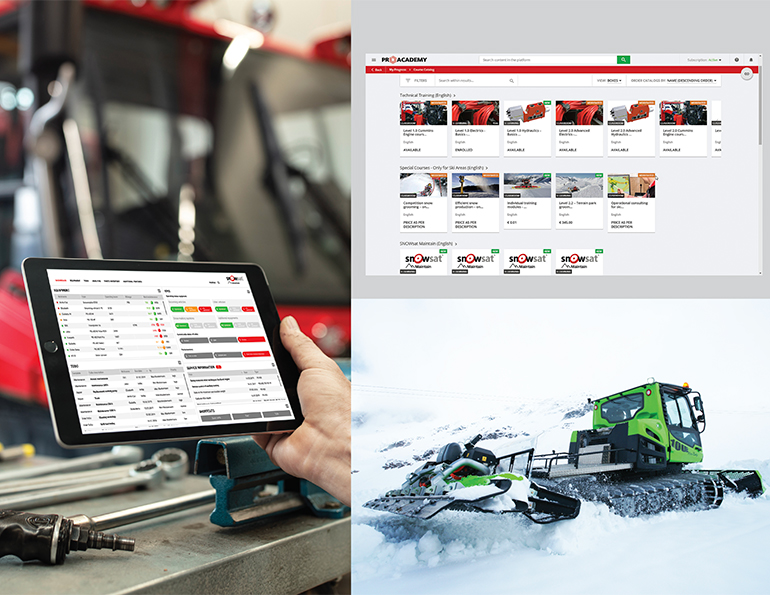

Left: The PistenBully SNOWsat family of software programs has digital solutions for maintenance, snow depth and fleet management, and more, including SNOWsat Maintain for use by vehicle maintenance. Top Right: PistenBully Pro Academy Technical Training covers a broad range. Above Right: The PistenBully 100E concept machine is helping PistenBully prepare for an all-electric future.

Left: The PistenBully SNOWsat family of software programs has digital solutions for maintenance, snow depth and fleet management, and more, including SNOWsat Maintain for use by vehicle maintenance. Top Right: PistenBully Pro Academy Technical Training covers a broad range. Above Right: The PistenBully 100E concept machine is helping PistenBully prepare for an all-electric future.

THE FUTURE

As both PistenBully and PRINOTH look to the future, two areas of particular interest relate back to Glockhamer’s original points of emphasis—the move toward zero-emissions machinery, and increased automation in the grooming process.

Fully unmanned automation, now used in other industries like mining, is not on the near horizon. Current software that brings automation to the aid of groomers makes operators more efficient, but it’s not replacing them.

“There are so many variables in snow grooming, especially with people [e.g., snowmakers, on-slope workers, skiers] around,” says Muigg. He adds, however, that “eventually we’ll get there.”

In the meantime, the various tools that SNOWsat and PRINOTH/Leica software put in the hands of groomers increasingly help assist and guide the grooming process. Somewhere along the line, a halfway step to full automation might be having a human controller remotely maneuvering unmanned machines from a base station. But to reiterate, this is not something anyone in the grooming industry sees happening any time soon. For the foreseeable future, the term “groomer” continues to carry both mechanical and human meaning.

PRINOTH

While neither company has yet hit the market with a true zero-emissions groomer, both have been working on prototypes. Muigg says PRINOTH is guided by “a strong belief in a zero-carbon footprint,” and says that the commercial introduction of a fully electric smaller groomer is “probably one or two years out.” The company has also been testing a hydrogen-fuel-cell driven vehicle, although he acknowledges that hydrogen-technology infrastructure, most notably the ready supply and storage of hydrogen, is still in its infancy, especially in North America.

PISTENBULLY

With the 600 E+, PistenBully is already involved in electric propulsion. In 2019, says Glockhamer, in a step toward a next-generation evolution, the company introduced a “concept” machine—a 100-percent electric-driven PB 100E groomer. It is now in its second season of testing, which involves simulating all conceivable applications under diverse conditions.

The challenge facing the program is maintaining a battery charge sufficient for an entire grooming shift. The 100E is currently able to operate for three hours before needing to recharge. “We’re not quite there commercially,” says Glockhamer. But clearly, all-electric vehicles are on PB’s horizon.

Whatever the future holds, the move toward sustainability in groomers has come a long way since EPA and NHTSA produced their first regulations on greenhouse gas emissions and particulate matter for heavy-duty diesel-powered vehicles, including groomers, 10 years ago. From that perspective, fully electric and fuel-cell cats don’t seem all that far-fetched.